For your sensitive products, Bernhardt accompanies you and designs several types of packaging machines for vacuuming and inerting. This process ensures optimal protection of your product by avoiding its deterioration by oxidation and/or moisture. Inerting is available on 3 different types of equipment that are offered according to the customer’s specifications; worked product (powder or solid), speed, number of operators on line.

The advantages of inerting with a neutral gas such as nitrogen

Inerting, also known as modified atmosphere, helps keep your product intact by avoiding the mechanical pressures generated by the vacuuming process. Gas injection or reinjections are also used to describe the process of replacing atmospheric air with a neutral gas, such as nitrogen. This ensures that the product remains stable during its transport and storage time. This is a particularly key process for powders and delicate foods.

Inerting has two main advantages:

- Quality: since it increases shelf life and; combined with barrier packaging, prevents oxygen and water vapour contamination that could cause degradation

- The fluidity of powder products: inerting avoids the effects of mottage and agglomeration caused by the vacuuming of powdered products. It avoids the denaturation of the product and the use of an emotteur for the end customer.

Types of equipment allowing inerting:

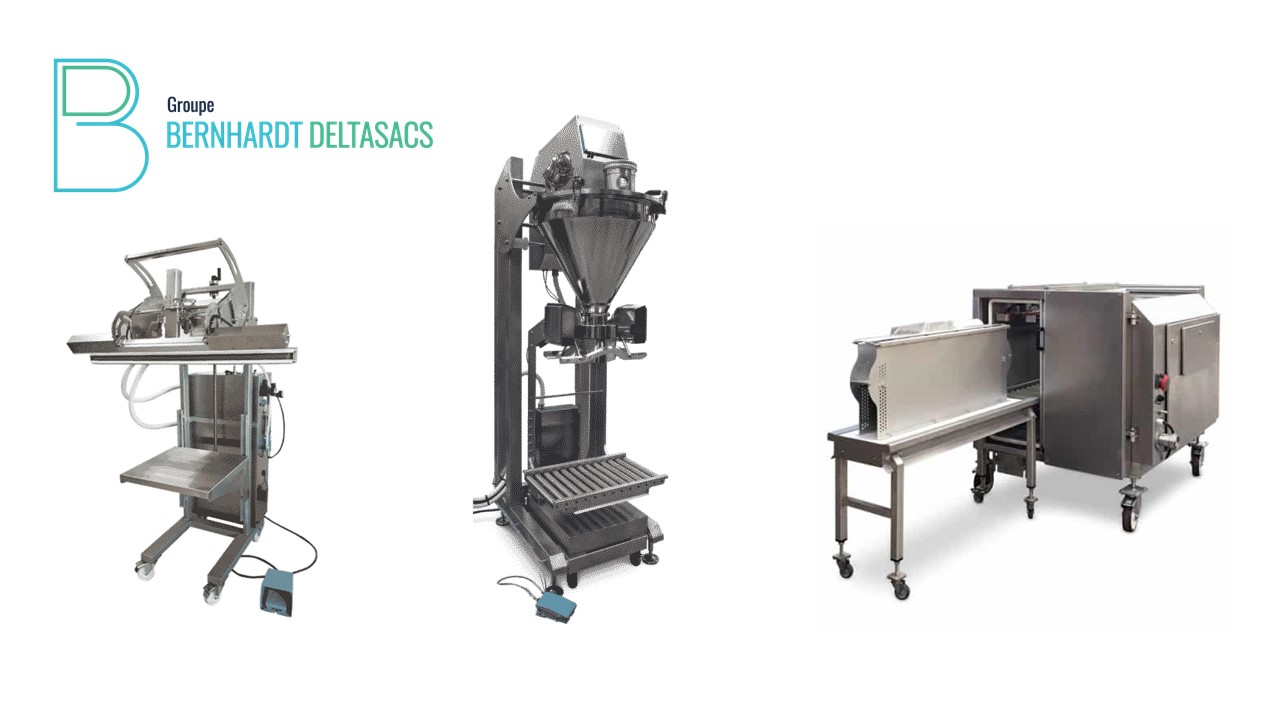

with a welder:

Bernhardt manufactures and designs vacuum welders with or without reinjection. This machine allows the vacuum and then the modified atmosphere of bags; bags and pockets made of barrier films. It is suitable for medium capacity packaging and non-powdery products.

with a vacuum bell:

The vacuum bell allows you to apply the vacuum and inerting process on 4-6 packages at a time. This equipment is suitable for bags, bags and bags made of coextruded or complexed barrier films. It is a recommended equipment for more volatile products since it allows precise control of the vacuum and reinjection flow; Guaranteeing a high-quality result without fine emissions.

with a big bag filling station:

The filling station is a machine for filling, vacuuming and inerting large containers. It is the right equipment for big-bags of 600kg, 800kg or even 1000KG. The filling station is recommended for powder or granular products in big-bags.

Bernhardt proposes the inerting process on 3 different machine typologies; in order to provide optimal protection to your products. The neutral gas used, usually nitrogen; will maintain the quality of your products while avoiding their external contamination. Available on welders, vacuum bells and filling stations, inerting is applied to packaging of varying size.

Need a machine offering inerting? Contact Bernhardt for a quotation!