Cosmetics

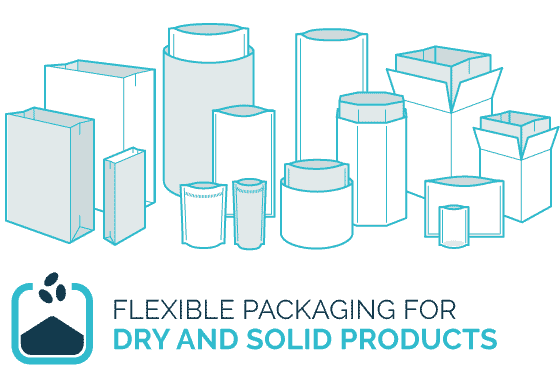

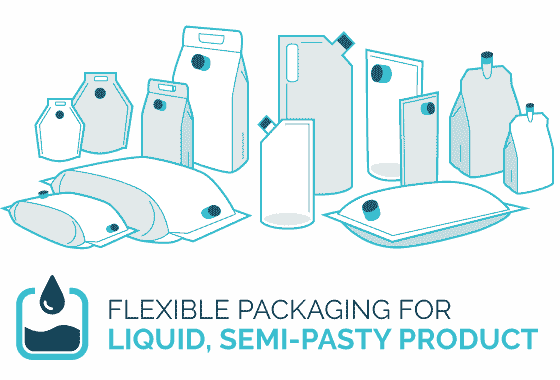

IndustryFlexible packaging solutions for the cosmetics industry

BERNHARDT is a major player in flexible packaging for the cosmetics industry. We design and produce primary and secondary packaging solutions that meet the quality, safety and performance requirements expected by players in the cosmetics sector, in France and abroad.

We attach particular importance to the traceability of our packaging, the control of the materials used and their compatibility with cosmetic formulations.

We support our customers in the challenges of the European PPWR regulation, which aims to reduce the environmental impact of packaging, promote its recyclability and harmonize requirements on a European scale. We offer packaging structures that comply with the reduction, recyclability and functional performance objectives defined by this new regulatory framework.

A TAILOR-MADE PACKAGING PROJECT ?

Our R&D and methods departments put their experience at your disposal to find a solution adapted to your specifications: specific dimensions, high level of mechanical resistance required, special formats, recyclability.

Our graphic design service also helps you to personalise your packaging with a qualitative and differentiating printing.

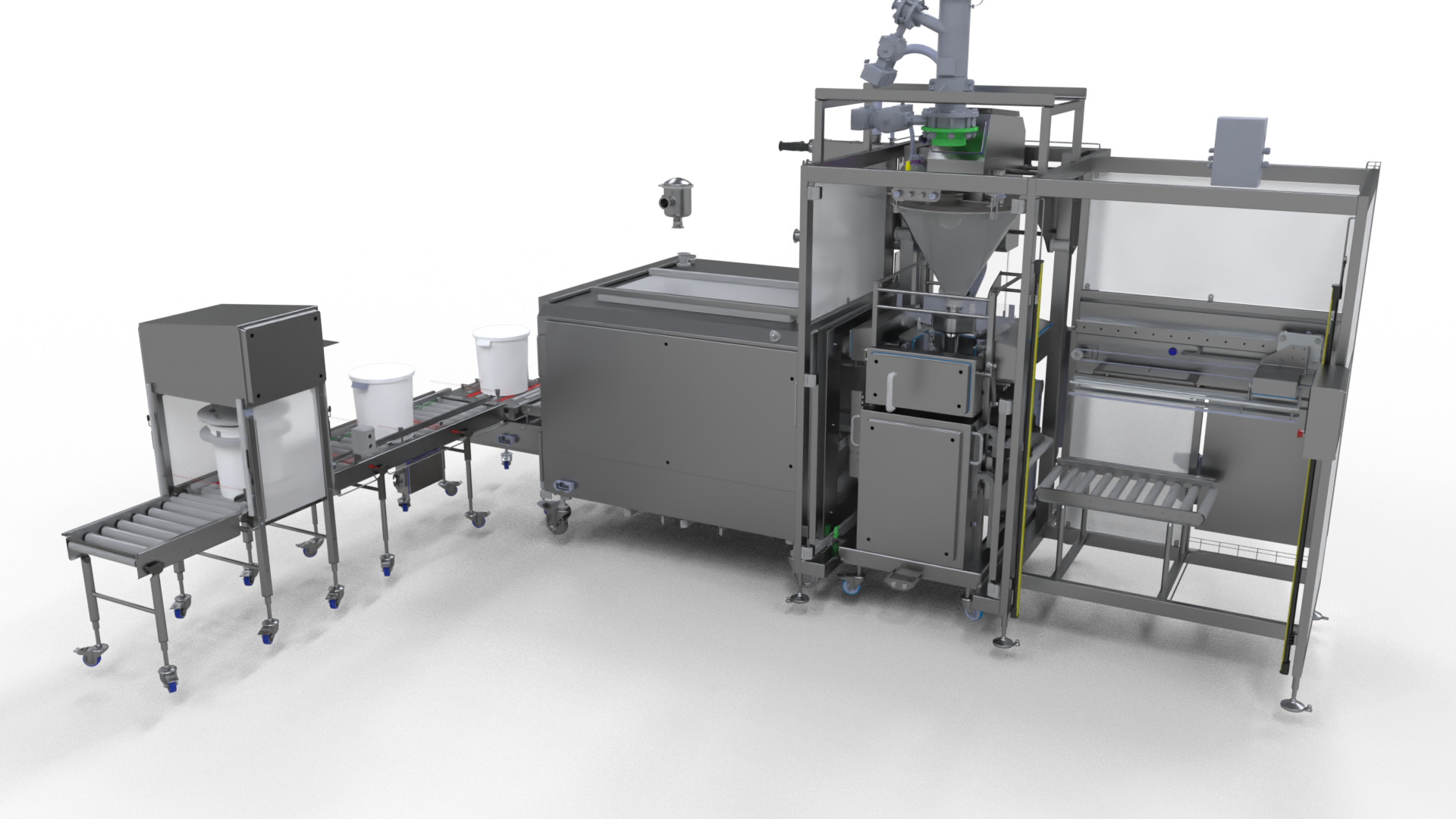

Packaging machines for the cosmetics industry

Bernhardt designs and manufactures in France packaging lines for the cosmetics industry, meeting the quality, precision and reliability requirements of industrial production environments.

We support our customers in the commissioning and validation of their equipment, by offering testing, adjustment and functional qualification services adapted to cosmetic processes. Our machines are made from robust, rust-free materials that are compatible with hygiene and cleaning requirements.

Our design office is involved in tailor-made design projects, from stand-alone machines to complete packaging lines integrating dosing/filling (powder products), weighing, vacuuming, and sealing functions.

Looking for specific equipment ?

We create packaging lines adapted to cosmetic processes, taking into account the expected functionalities, the constraints of implementation and the optimization of production flows.